Feb 22, 2021

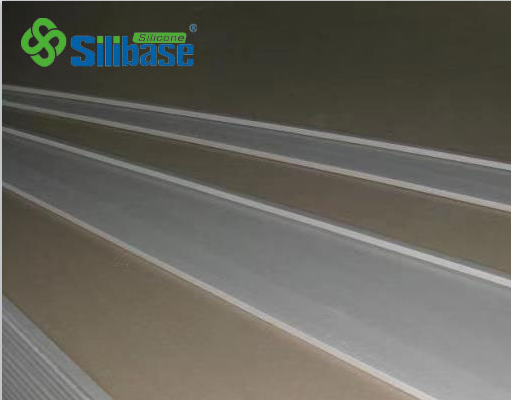

Waterproof gypsum board means that the water absorption rate of this kind of stone board is 5% when the standard is used for waterproof test, that is, it can be used in areas with high humidity, such as toilets, shower rooms and kitchens, etc. The board is added to the gypsum core material Quantitative waterproofing agent makes the plaster itself have a certain waterproof performance. In addition, gypsum board paper is also waterproofed, so this is a better board with a wider range of uses. However, this board should not be directly exposed to a humid environment, nor can it be directly immersed in water for a long time.

Gypsum board is mainly used for engineering or home decoration. Because of its good toughness (suitable for special-shaped tops) and relatively cheap price, it has always been the first choice for the majority of decorators. Secondly, the gypsum board itself is a secondary crystalline product, and the water crystals contained therein can effectively achieve the effect of heat absorption, and the fire prevention effect is more significant. In addition, because of the foaming agent, the gaps are properly arranged in the plaster, which has the effect of sound insulation and sound absorption. Moisture-resistant series are made of moisture-proof treatment on the paper surface of the gypsum board. The water-resistant gypsum board is the core gypsum that has also been water-resistant. Moisture-resistant boards are mainly used in basements or indoor places with high relative air humidity and high construction requirements. Water-resistant gypsum board is commonly used in bathrooms or kitchens. Of course, there are many fireproof and waterproof materials on the market, such as calcium silicate board and FC board. There are glass magnesium boards that are fire-resistant and moisture-resistant. However, because of the characteristics of their own materials, they limit their scope of use. Therefore, they cannot replace the dominant position of gypsum board for the time being.

Gypsum board is a lightweight construction sheet made of natural gypsum and protective paper as the main raw materials, mixed with appropriate amounts of fiber, starch, coagulant, foaming agent, and water. The performance has the following characteristics:

Low energy and high efficiency

The energy consumption of producing the same unit of gypsum board is 78% less than that of cement. In addition, the investment is small and the production capacity is large, the process is simple, and it is convenient for mass production.

Lightweight

Using paper-faced gypsum board as the partition wall, the weight is only 1/15 of the brick wall of the same thickness and 1/10 of the block wall, which is beneficial to the earthquake resistance of the structure and can effectively reduce the cost of the foundation and the main structure.

thermal insulation

Fire performance

Since the gypsum core itself is incombustible and will absorb a lot of heat in the process of releasing the chemical water when it encounters fire, and delay the rise of the surrounding environment temperature, the paper-faced gypsum board has good fire and flame retardant properties. Tested by the National Fire Inspection Center, the fire resistance limit of the gypsum board partition wall can reach 4 hours.

Sound insulation performance

The single-layer wall composed of a single lightweight material, such as aerated concrete, expanded perlite board, etc., can meet the requirements of sound insulation when its thickness is large, while the paper-faced gypsum board partition wall has a unique cavity structure and has a very Good sound insulation performance.